Crafting Excellence: Materials Test Lab Mastery for Guarantee

Wiki Article

Placing Materials to the Test: Exploring the Duty of Materials Examination Labs

Materials examination labs play an essential duty in making sure the quality and integrity of different materials used in markets such as building and construction, production, and aerospace. These labs carry out extensive testing to review the efficiency, stamina, resilience, and safety of products, allowing firms to make enlightened decisions regarding their usage in items and structures. Through a mix of advanced methods and specialized equipment, materials test labs have the ability to evaluate the buildings of steels, polymers, compounds, and other products under various problems and stress factors. The outcomes gotten from these examinations supply important insights right into material actions, permitting engineers and designers to maximize their products and procedures. This write-up will certainly explore the importance of products testing, the sorts of materials tested, testing strategies and devices used, along with the applications of materials examination results. Furthermore, it will certainly discuss future fads in materials screening, highlighting the continuous advancements in this area.Value of Products Screening

Routinely examining the top quality of products is crucial in guaranteeing the stability and security of items in numerous sectors. This is where products screening plays an essential duty. Products screening entails subjecting products to numerous examinations and experiments to examine their mechanical, physical, and chemical buildings. By performing these examinations, distributors and suppliers can guarantee that their products fulfill the called for criteria and specs.One of the crucial reasons why products screening is important is the assurance of item high quality. With extensive screening, manufacturers can identify any type of issues or weaknesses in the products used for their products.

By subjecting materials to numerous examinations, producers can determine their resilience, resistance, and toughness to outside factors such as warmth, pressure, or chemicals. Whether it is automobile parts, medical devices, or building and construction materials, products testing aids in determining any possible security threats and establishing appropriate procedures to mitigate them.

Sorts Of Materials Examined

Various sorts of materials are checked in materials test laboratories to assess their mechanical, physical, and chemical residential properties. These materials can include a large range important, including steels, polymers, ceramics, composites, and even all-natural materials such as timber and concrete.Metals are generally evaluated because of their prevalent use in different sectors. These examinations examine buildings such as tensile strength, solidity, and ductility. Polymers, on the various other hand, are evaluated to determine their flexibility, thermal stability, and resistance to chemicals. Ceramics are taken a look at for their resistance, brittleness, and strength to high temperatures. Compounds, which are composed of 2 or even more different materials, are reviewed to understand their overall performance, consisting of aspects like adaptability, toughness, and durability.

Natural materials like timber are evaluated to evaluate their toughness, moisture web content, and resistance to degeneration (materials test lab). Concrete is another generally checked material, with examinations focusing on its compressive toughness, longevity, and resistance to ecological variables

In addition to these products, materials examination labs also examine layers, paints, adhesives, and different other materials utilized in construction, production, and other sectors. By subjecting these materials to strenuous screening, engineers and scientists can collect valuable information to inform material option, layout optimization, and quality assurance procedures.

Evaluating Strategies and Equipment

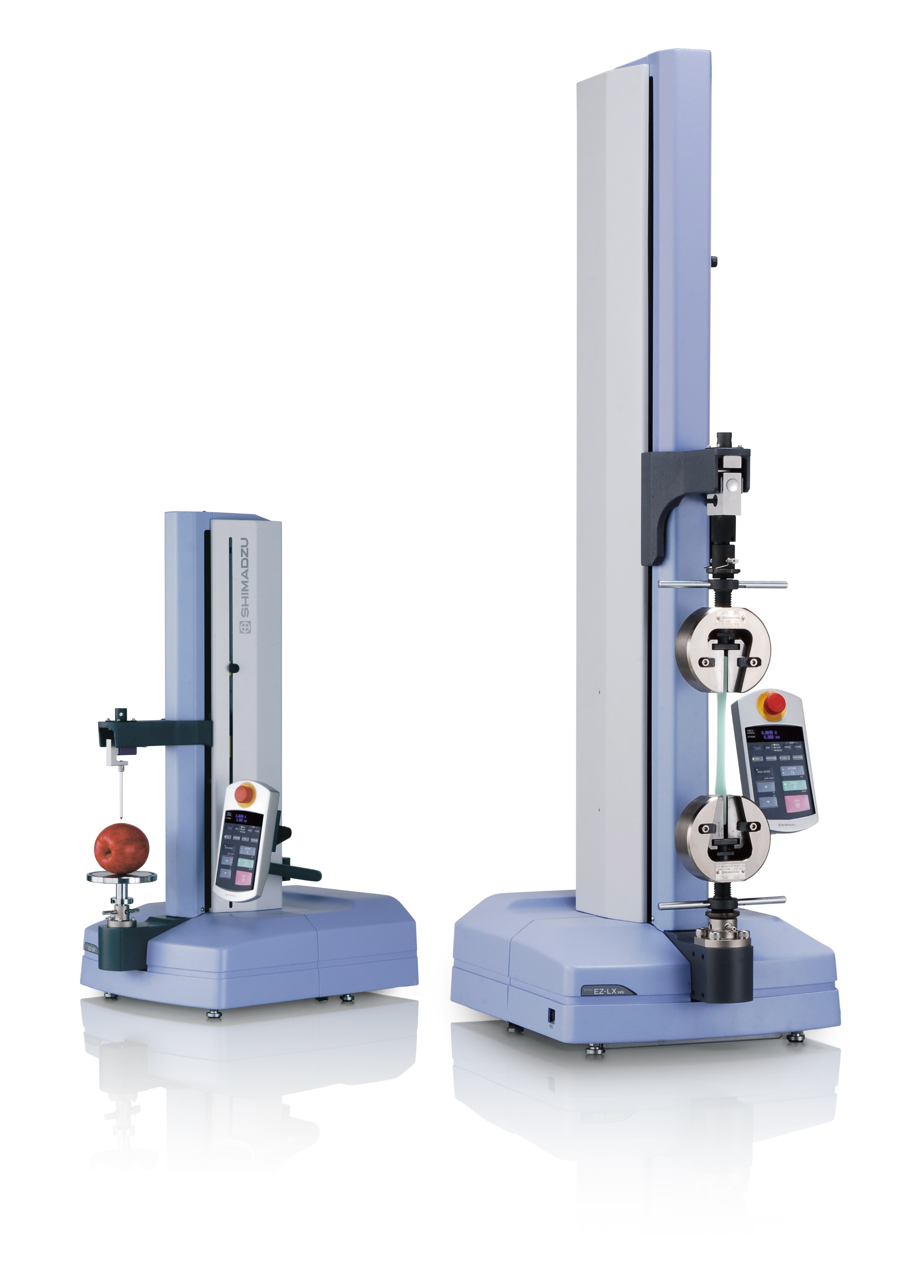

Checking strategies and equipment play a crucial duty in materials test labs for reviewing the mechanical, physical, and chemical residential properties of various materials. These methods and equipment are necessary in guaranteeing the high quality, integrity, and safety of materials utilized in various markets such as aerospace, auto, construction, and medical.One frequently made use of screening technique in products test labs is mechanical testing, which involves subjecting materials to different pressures or tons to establish their toughness, hardness, ductility, and other mechanical buildings. This is often done using equipment such as universal testing devices, which can use tensile, compressive, and flexing pressures to examine samplings.

Physical screening strategies are additionally utilized to examine buildings such as density, thickness, thermal conductivity, and electric conductivity. Tools such as thickness meters, viscometers, thermal conductivity analyzers, and electric conductivity meters are utilized to carry out these tests accurately.

Chemical testing methods are used to identify the chemical composition and purity of materials. Techniques such as chromatography, mass, and spectroscopy spectrometry are generally utilized, together with specialized equipment made for these functions.

Applications of Products Examination Outcomes

The outcomes of materials checking provide valuable insights into the performance and suitability of various products for details applications in numerous sectors - materials test lab. These examination results play a critical duty in establishing the top quality, durability, and safety of products used in producing processesOne of the essential applications of materials test results remains in the area of building. Engineers and engineers rely upon these results to pick proper materials for building structures, such as bridges, skyscrapers, and residential structures. By carrying out tests on products like steel, concrete, and hardwood, they can make sure that these materials fulfill the needed requirements and can withstand different ecological conditions.

In the aerospace industry, products test results are crucial in figuring out the suitability of materials for aircraft components. By subjecting products to strenuous screening, engineers can assess their mechanical homes, resistance to heat and rust, and ability to hold up against high-stress conditions. index This details is important in guaranteeing the safety and security and dependability of airplane.

Future Patterns in Products Testing

In the world of products testing, developments in products checking methods are forming the trajectory of the field, ushering in a brand-new period of advancement and accuracy. One future pattern in materials testing is the integration of artificial knowledge (AI) and maker knowing algorithms right into testing procedures. These techniques allow for the Learn More Here analysis of material residential properties without triggering damages or modification to the sample, making them excellent for checking important or irreplaceable products.Conclusion

In verdict, products testing plays a vital duty in various industries by guaranteeing the top quality, safety and security, and performance of materials utilized in frameworks and items. The outcomes gotten from products screening are made use of to make enlightened decisions in material selection, production, and design processes.With a combination of sophisticated methods and specialized equipment, materials examination laboratories are able to analyze the properties of steels, polymers, compounds, and various other materials under various conditions and stressors. By performing examinations on materials like lumber, steel, and concrete, they can make certain that these products satisfy the required standards and can hold up against numerous environmental conditions.

In the aerospace sector, materials test results are vital in identifying the viability of materials for airplane elements. By testing products for their flexibility, resistance, and toughness to effect, manufacturers can choose the most suitable products for different vehicle components, such as body panels, engine components, and safety functions.In the world of materials screening, innovations in products testing techniques are shaping the trajectory of the area, ushering in a new age of technology and precision.

Report this wiki page